AZL PARTNERSHIP

AZL Partnership – Joining Research and Industry

With the common goal to establish close cooperation between top research bodies and industry, academic staff, researchers and students will now be working side by side with the employees of innovative business companies.

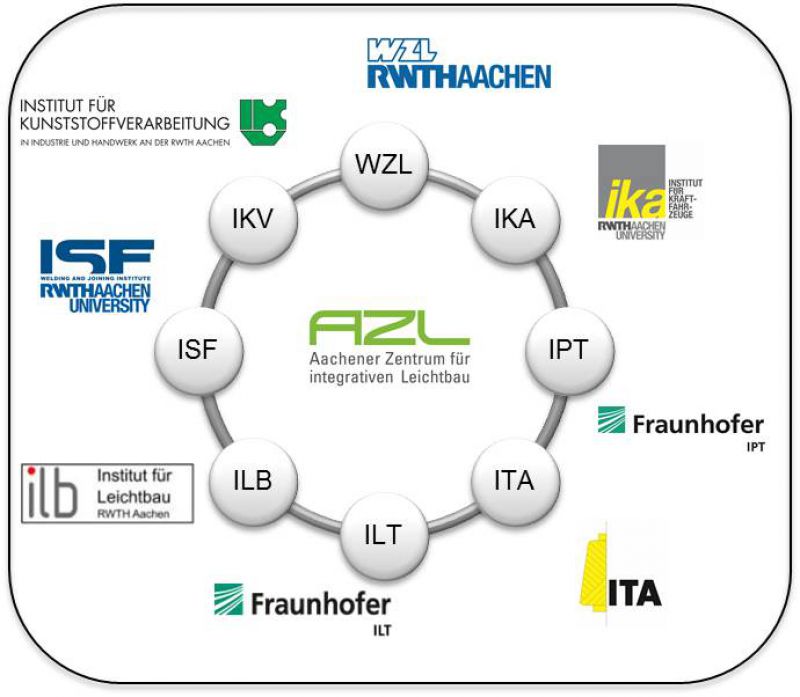

As one of the first institutions on the new campus in Aachen, the Aachen Center for Integrative Lightweight Production (AZL) will be set up. The aim is to develop the automated production of load-and cost-optimized lightweight components, suitable for mass production and versatile process chains in composite and multi-material design. All the necessary expertise along the entire value chain is within walking distance on the campus assembled around the AZL, where over 700 scientists are working on production technology and lightweight constructions. In addition to the existing excellence in production technology of the RWTH Aachen, this network of competence in lightweight construction at one single location is unique worldwide.

The AZL Aachen GmbH is the co-operative service provider in integrative lightweight production. Since its beginning in October 2012, AMAC supports the AZL for strategic advisory and for the development of their partnership business model. In May 2014, the AZL counts more than 50 international industrial partners along the entire value chain. The expertise covers the production from carbon- and glass fibers, textile preforming, high-volume capable plastics processing, automation, machining and testing to applications ranging from oil, water, gas, infrastructure, buildings to and automotive engineering.

“To develop an integrated, automated approach to composites production which is suitable for high-wage countries, is the aim of AZL”, explains Dr Michael Effing, CEO of AMAC GmbH. He continues: “In this business model, we try really a new fundamental approach to integrate all the elements along the value chain, so the know-how from thermoplastics, from thermosets, the fibres etc., the tool designs, the robotics, the machinery, and at the end of the day, it’s ideally fully-automated, with as little labour content as possible, but high quality and consistent quality.”

For further information about the services provided by AZL please read the brochure or check the AZL webpage

www.azl-aachen-gmbh.de